Tanaka Kazuyuki Hamono

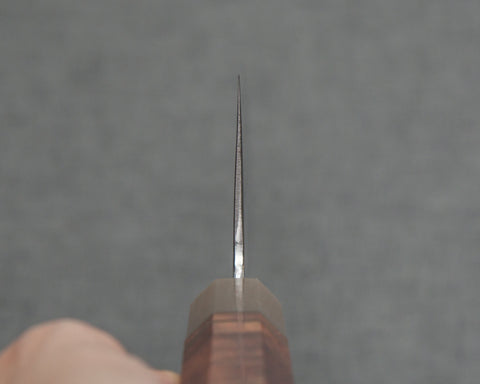

Shigeki Tanaka R2/SG2 Damascus 270mm Gyuto

Pickup currently unavailable

This Gyuto is handcrafted by Shigeki Tanaka with R2/SG2 steel, heat-treated to 63 HRC. The blade features a mesmerizing Diamond Damascus finish, and the beautiful edge geometry and distal tapering ensure a sleek cutting performance. Paired with a premium Rosewood wa-handle with Buffalo Horn Kuchiwa and triple Ginmaki.

Spec:

- Origin (Made in): Miki, Hyogo Prefecture, Japan

- Brand: Tanaka Kazuyuki Hamono

- Craftsman: Shigeki Tanaka

- Knife Type: Gyuto

- Blade

- Construction: San Mai

- Grind: Double-edged Blade (50/50 Grind)

- Hagane (Core Steel): R2/SG2

- Jigane (Cladding): Stainless Steel

- Hardness: 63 HRC

- Hand-forged, hand-grinded, hand-sharpened

- Blade Finishes: Damascus

- Blade Length: 270mm (10.6")

- Blade Height (at heel): 57mm

- Spine Thickness

- Above heel: 2.6mm

- Middle: 2.3mm

- Handle

- Premium Luxury Custom Handle

- Shape: Hachikaku (Octagonal)

- Material: Rosewood (Dalbergia Odorifera)

- Kuchiwa / Tsukajiri: Marble Buffalo Horn

- Divider: Rosewood (Dalbergia Odorifera)

- Ginmaki: Nickel Copper (x3)

- Length: 145mm

- Overall Length: 426mm

- Weight: 238g (8.40oz)

- Mark (Front): In Japanese Kanji "Craftsman Shigeki's Work" (名匠 誠貴作)

- Mark (Back): In Japanese Kanji "Minamoto" (源)

- Comes in a Paulownia wood box

About Tanaka Kazuyuki Hamono 田中一之刃物

Tanaka's blade making started in the late Meiji era in 1904, by making sickles during the Russo-Japanese War. In 1946, Tanaka workshop started focusing more on kitchen knives, and in year 2000 with the 3rd generation Kazuyuki Takana (田中 一之) on the throne, the family business changed its name to "Tanaka Kazuyuki Hamono" and has been using this name since. Kazuyuki's son - 4th generation blacksmith Shigeki Tanaka (田中 誠貴) - started making blades with his father in 1994. The father and son team, having learnt traditional blade making in Fukui, started making knives with "Shigeki saku" and “Hideyuki saku” mark.

Care:

Wash and dry with a soft sponge, and safely store after use. Avoid cutting into bones, frozen foods, hard fruit pits.

Cutting Surface:

Recommended cutting surface: wood, rubberized boards and high-end composites, and quality plastics such as polyethene make acceptable cutting surfaces, and will help protect and prolong knife’s edge. AVOID glass, metal, countertops, and other rigid, non-forgiving surfaces.

Sharpening:

We recommend sharpening all quality Japanese knives on whetstones, as we believe they yield the best results for your knives.

Free Shipping

Free Shipping on most orders.

30 Days Return

Return unused within 30 days for a full refund, no questions asked (terms apply).

Top Japanese Makers

All knives made in Japan by top Japanese knife makers.

About

Burrfection Store sources professionally designed sharpening products, and knives from top Japanese craftsmen.