Yoshikazu Tanaka

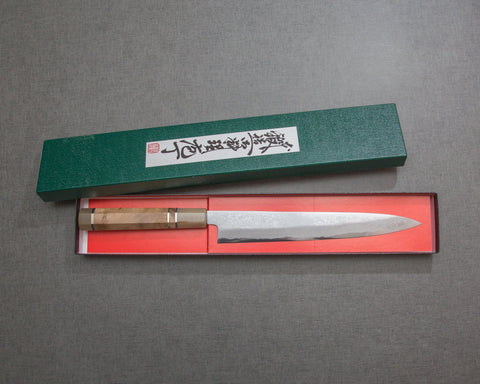

Yoshikazu Tanaka Shirogami #1 Damascus 240mm Sujihiki with Camphor Wood Buffalo Horn Handle

Pickup currently unavailable

This knife is handcrafted by famous Sakai artisan Yoshikazu Tanaka with Shirogami #1 as core steel. With an impressive Damascus cladding using soft iron, the knife is beautifully grinded with a Kasumi polish. With a higher carbon content than Shirogami #2, Yoshikazu-san was able to heat treat the steel to a hardness level of 64-65 HRC, enabling superior edge retention. Owing to the much narrower quenching temperature range than that of Shirogami #2, there are only a handful of artisans in Sakai who are capable of forging with Shirogami #1 steel. Yoshikazu-san has chosen to give the knife a thicker spine, so it's a great knife for those who prefers a more sturdy and robust handling. Despite the thicker spine, the grind tapers beautifully, and the knife has extraordinary thinness behind-the-edge, giving you one of the best cutting experiences. The blade is paired with a Camphor Wood handle with a Marble Buffalo Horn kuchiwa and triple nickel copper ginmaki.

Spec:

- Origin (Made in): Sakai, Osaka Prefecture, Japan

- Craftsman: Yoshikazu Tanaka 田中 義一

- Knife Type: Sujihiki

- Blade

- Construction: San Mai

- Grind: Double-edged Blade (50/50 Grind)

- Hagane (Core Steel): Shirogami#1 (White #1)

- Jigane (Cladding): Soft Iron

- Hardness: 64-65 HRC

- Hand-forged, hand-ground, hand-sharpened

- Blade Finishes:

- Damascus

- Kasumi Polish

- Blade Length: 240mm (9.4")

- Blade Height (at heel): 37mm

- Spine Thickness

- Above heel: 2.9mm

- Middle: 2.2mm

- Handle

- Premium Custom Handle

- Shape: Hachikaku (Octagonal)

- Material: Camphor Wood

- Kuchiwa: Marble Buffalo Horn

- Ginmaki: Nickel Copper (x3)

- Length: 145mm

- Overall Length: 390mm

- Weight: 176g (6.21oz)

- Engraved Mark: In Japanese Kanji "Shirogami#1" (白紙 壱号)

About Yoshikazu Tanaka 田中 義一

Yoshikazu Tanaka is an old-school artisan, who focuses on making knives only with Shirogami steel and Aogami carbon steel. With over half a century of experience in making knives, he trusts his own intuition and skills more than modern tools. For example he tells the temperature of the steel by looking at its color, rather than using a thermometer. But at the same time, he seeks improvement over time, and uses usual tools during the knife-making process. He uses pine charcoal, ash of straw and a temperature-controlled kiln for heat-treating and forging his knives. At the moment, he only makes 30 knives a day with his team in his workshop located in Sakai City.

Care:

Shirogami #1 (white #1) steel is one of the popular types of high carbon steel found in Japanese kitchen knives (Wa Knives). It is not stainless, therefore you must wipe your knife dry after each use. Patina will develop over time. Rust may develop if left in prolonged contact with water or acidic food. Use a rust eraser to clean if rusts develop. Avoid cutting into bones, frozen foods, hard fruit pits.

Cutting Surface:

Recommended cutting surface: wood, rubberized boards and high-end composites, and quality plastics such as polyethylene make acceptable cutting surfaces, and will help protect and prolong knife’s edge. AVOID glass, metal, countertops, and other rigid, non-forgiving surfaces.

Sharpening:

We recommend sharpening all quality Japanese knives on whetstones, as we believe they yield the best results for your knives.

Free Shipping

Free Shipping on most orders.

30 Days Return

Return unused within 30 days for a full refund, no questions asked (terms apply).

Top Japanese Makers

All knives made in Japan by top Japanese knife makers.

About

Burrfection Store sources professionally designed sharpening products, and knives from top Japanese craftsmen.